Earlier in 2020 Ropepro assisted AGL and the team at Black Geo technical with the inspection of the Clover pressure incline tunnel which is part of the Kiewa Hydro Electric Scheme near Mt Beauty, Victoria. The tunnel required inspection of the rock walls and ceiling to record the general condition of the tunnel as well to ensure there were no rock fall hazards that may pose a threat to workers during proposed maintenance works in the near future. The tunnel itself was approximately 100m long and 4m in diameter with a gradient of 50 degrees. Further information regarding potential hazards within the tunnel was difficult to ascertain as the tunnel had not been entered since it was constructed 75 years ago. In addition to this, much of the preliminary assessment and the assumed environment of the Tunnel was based off plans and drawings of the Tunnel drawn up during the time of the Tunnel’s planning and construction.

During the weeks and months leading up to the project commencement date, Ropepro worked closely with the AGL and Black Geo technical project management teams in the development of a Safe Work Method Statement and Rescue Plan to ensure the task hazards, risks and possible emergency scenarios were considered and controlled. These documents and plans required the flexibility to be reviewed and amended during the project to allow for emergent factors and hazards to be considered and controlled throughout the course of the project. Plans also needed to consider such potential scenarios as: air quality, communication between entrants and stand-by operatives, access to and treatment of a casualty or multiple casualties and the hauling or lowering of a casualty/ies through and out of the tunnel system whilst negotiating multiple hazards.

Prior to entry in to the Tunnel, anchor points were required to be installed in to the rock at the entrance of the tunnel to allow four abseilers to descend. Careful assessment of the rock was made by the Black Geo technical Engineers, Billy Burke and Nick Schofield, to ensure the rock was sound and suitable for use as a parent structure for the anchors. The Anchor points were then installed in to the rock face and load tested in accordance with manufacturer’s specifications and the Australian/New Zealand Standards.

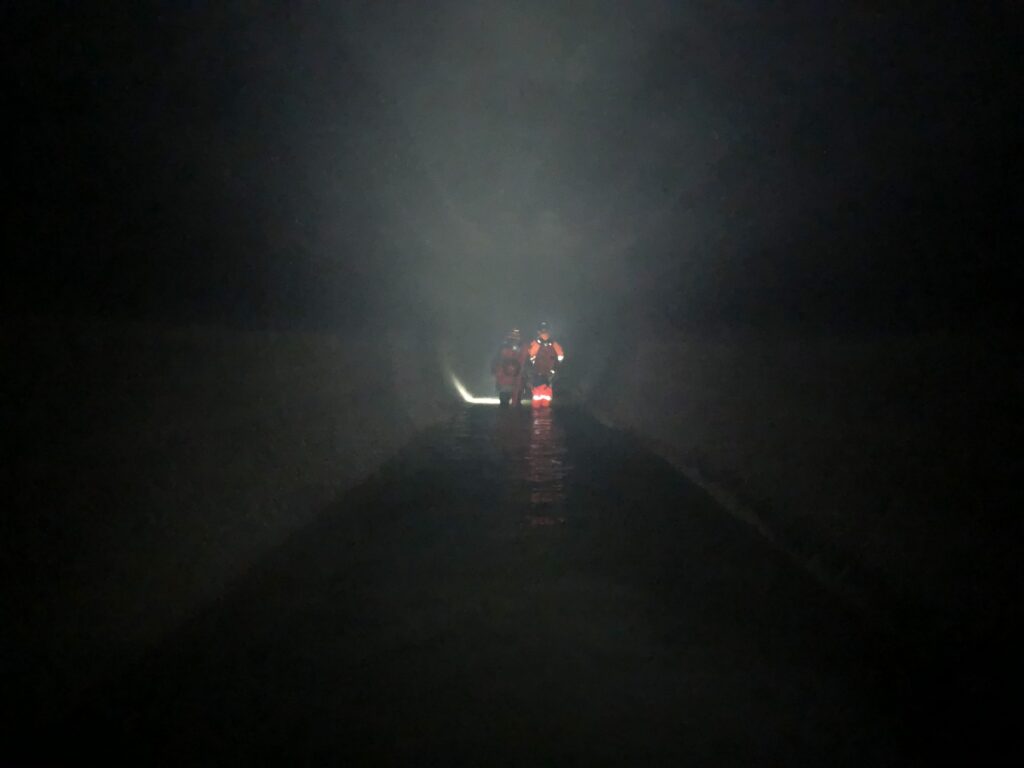

An emergent hazard that was identified prior to entry was the presence of residual water at the head and entrance of the Tunnel. Although water had been isolated from the tunnel there was still the presence of water entering and falling through the tunnel during the inspection which created slip, trip and fall hazards as well as noise and communication hazards. By extension, another hazard that was identified was the risk of hypothermia due to the tunnel entrants being constantly exposed to cold water and cold temperatures for up to 3 hours at a time.

Through careful planning, consultation and execution by the project teams across several coordinated groups the inspection was carried out successfully and without incident in what proved to be a unique and challenging environment. The Geo technical Engineers were able to safely access the Tunnel under the Supervision of Rope pro site Supervisors to record accurate information relating to its condition to the satisfaction of our customer, AGL.